What is color steel plate

Light steel house is composed of composite steel plate (also known as the color steel sandwich panel) wall, and with light steel skeleton building.

Light color steel plate composite panels (hereinafter: color plate) is classified according to different core material: polyurethane sandwich plate, rockwool board, polystyrene (EPS) sandwich plate, glass wadding sandwich board etc..

The shell of the color plate is a color coated steel plate, and the color coated steel plate is a steel plate with an organic coating.

1 color steel plate six characteristics of 1 light weight: 10-14 kg / square meter, equivalent to brick wall 1/30

2 thermal insulation: core material thermal conductivity: lambda <=0.041w/mk.

3 high strength: can be used for ceiling envelope plate bearing, bending resistance; general housing without beam column

4 bright color: no surface decoration, color galvanized steel anti-corrosion layer to maintain a period of 10-15 years.

5 flexible installation: construction cycle can be shortened by more than 40%.

6 oxygen index: (OI) 32 (provincial fire products quality inspection station).

The substrate of the color coated steel plate is a cold-rolled substrate, a hot-dip galvanized substrate and an electro galvanized substrate. Coating types can be divided into polyester, silicone modified polyester, PVDF two and plastic sol. The surface state of color coated steel plate can be divided into coated sheet, embossing plate and printing plate, color coated steel appliances widely used in construction and transportation industries, the construction industry is mainly used in steel plants, airports, warehouses and other industrial and commercial refrigeration roof of the building walls and doors, building color steel less. It is the difference between the different materials and plastic. Magnet can suck.

Strictly speaking, distinction, and plastic color in the metal surface treatment characteristics and is not very good because the same; now the distinction between the main market in profile structure.

As is common carbon steel magnet can suck. Also note, adding chromium in stainless steel is low carbon just on the basis of (more than 13%) after the product, so the magnet will not suck. Magnet can prove whether the non-ferrous materials.

In the late 80s of last century, China began to build color steel plate units, these units are built in steel mills and joint ventures, color steel plate process equipment imported from abroad. By 2005 domestic color steel reached 1 million 730 thousand tons, the emergence of excess capacity. A large state-owned iron and steel enterprises Baosteel, Anshan, Shougang, Tang Gang, Jinan, Kunming, Handan, Wuhan, Panzhihua Iron and steel enterprises unit capacity, equipment level is higher, all have been built using thecolorplate units of foreign technology, the annual production capacity of 120 thousand tons to 170 thousand tons.

At the same time, many private enterprises to invest in color steel production mostly using domestic equipment, production capacity is small, but launched fast, low investment, products mainly for building materials, decoration industry. In addition, foreign investment, Taiwan have also landed to build color coating units, but most concentrated in coastal areas. Since 1999, with the color coated plate market boom, color coated plate production and consumption into the rapid growth period. From 2000 to 2004, production increased by an average of 39%. By 2005, the national color coated plate production capacity of more than 8 million tons / year, there are a number of color coating units under construction, the national total production capacity of more than 9 million tons / year.

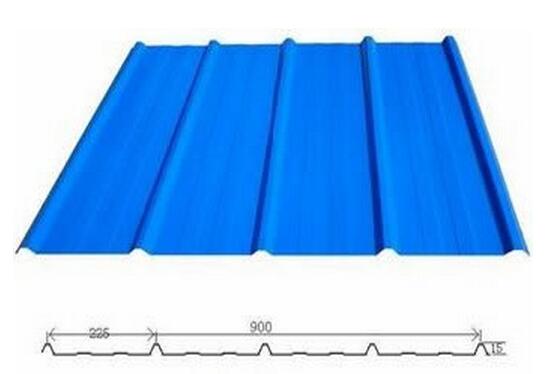

Color steel plate form: before the molding is coiled, forming a lot of models, the most commonly used: type 820, type 840, and so on, and so on! Its composition is: protective film (now no product), polyester paint, galvanized layer, steel plate (sub cold-rolled plate and hot-rolled plate), the same back the order of! The above analysis does not represent authority!